Thread patching, locking sealing and lubrication

Thread patching, locking sealing and lubrication

Looking to have an additional process added to existing security fastener stock? Discover how patches are used on fasteners and learn more about their unique features and abilities.

At Hafren Fasteners we offer 4 main types of patches on threaded fasteners:

- Re-usable thread locking (Nylon)

- Single-use thread locking (Adhesive)

- Thread sealing

- Thread lubrication

Choosing the right type of patch for your application will depend on certain key factors:

| Application

1. Patch must be removable/re-usable 2. Requires maximum holding strength in a one-use patch 3. Patch provides a leak resistant seal 4. Anti-Seize Products |

Best Patch Material

Nylon Patch Chemical Patch Sealing Patch Lubricants and Waxes |

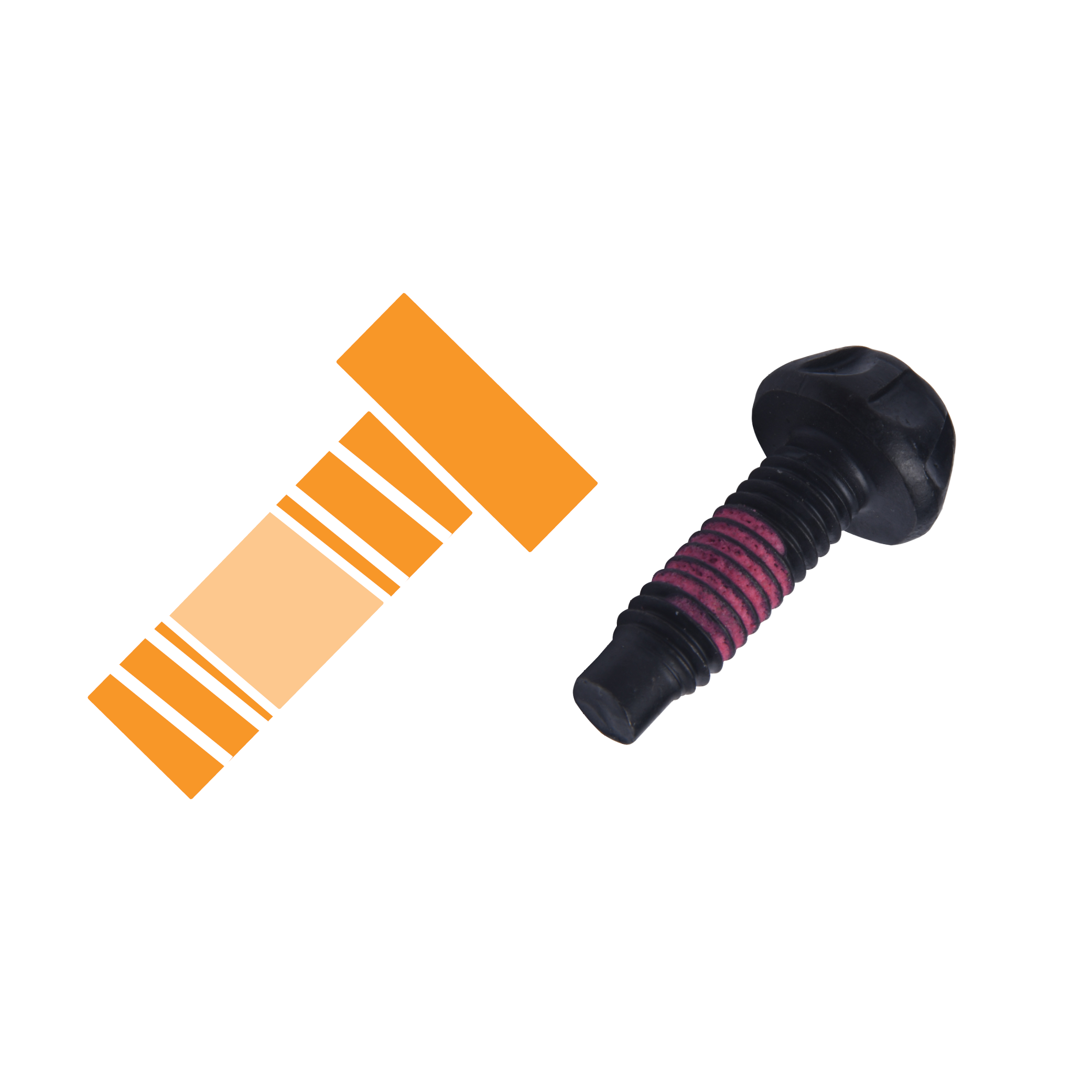

Thread locking (Nylon)

Nylon patched screws and nuts are re-usable. They can be disassembled and reassembled up to five times and still provide a locking action. High temperature orange patches with 260°C capability are available.

Pre-applied Nylon patch thread locking is a prevailing torque patch used to prevent fasteners becoming loose due to vibration or no load. When the fastener is assembled onto a mating thread, the patch forces the threads of the fastener to be wedged tightly against the mating thread, providing resistance to loosening. Torque Performance can be varied to suit specification/application requirements.

Available either as a 180-degree patch or a 360-degree gas seal patch around the thread.

- 180 anti-vibration locking patch, is a coloured nylon 11 feature permanently fused to the screw thread. This process provides excellent vibration resistance and torque performance for all applications requiring controlled loading and re-usability. The anti-vibration locking patch, is effective, whether or not the fastener is fully seated, making it ideal for applications where subsequent adjustment is required.

- 360 nylon anti-vibration locking patch, gives full circumference coverage (completely around the thread) and is suitable for applications requiring a fully re-usable high-pressure seal against liquid or gas.

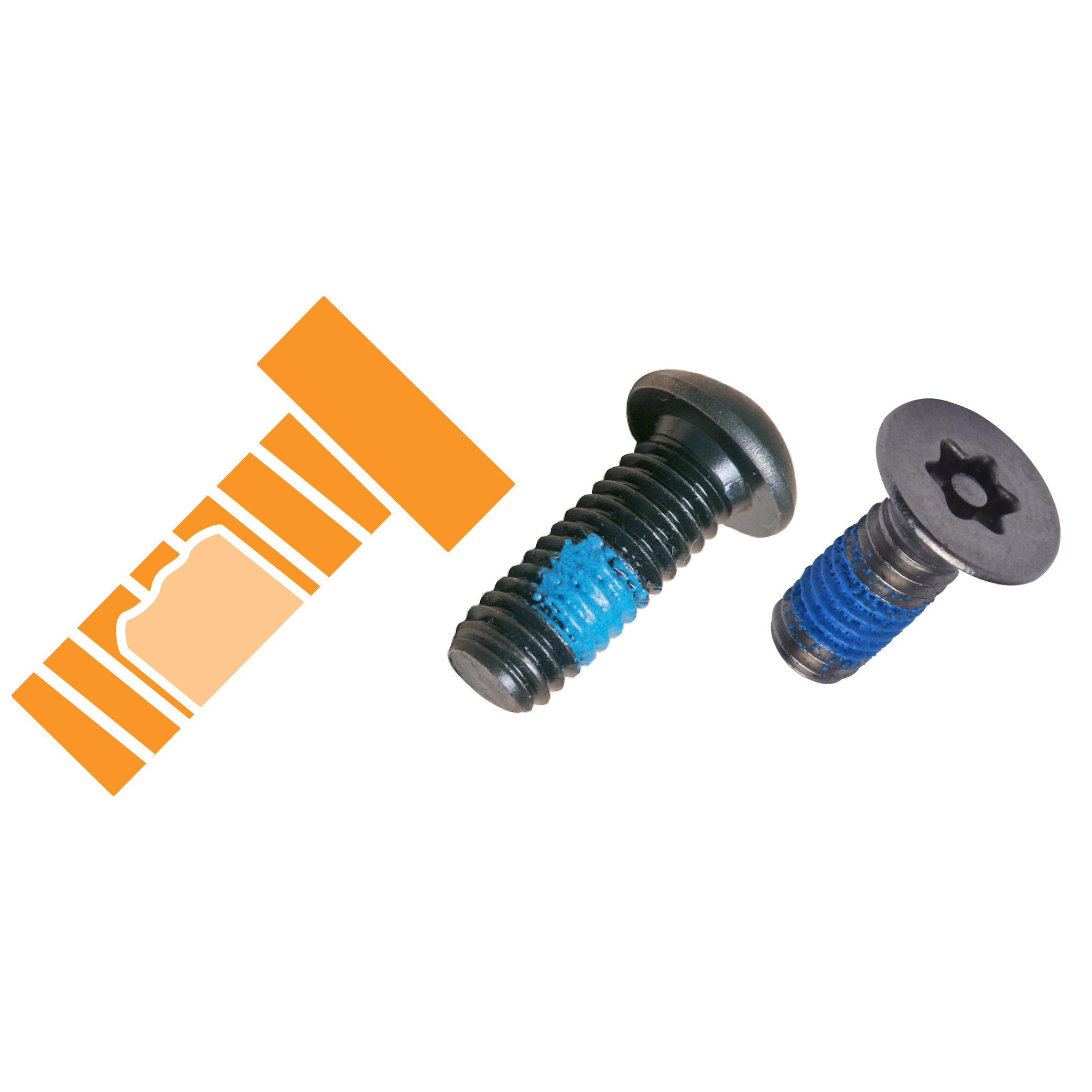

Chemical Patch (Micro-Encapsulated Adhesive)

Pre-applied single-use adhesive thread patch, which offers maximum holding strength. The adhesive patch that is applied to the threads will not cure until the screw is assembled onto a mating thread and is sealed from the air (known as anaerobic adhesives). Chemical patches are applied a full 360° around the thread and come in various formulas. Depending on the applicator, the adhesive can be epoxy or acrylic based. The pre-applied chemical patch also provides the convenience of having the patch already present on the threads, without the need for the assembler to remember to apply a liquid patch at the time of assembly. Pre-applied chemical patches are available in various formulas that determine how much holding power they provide (from medium strength to high strength).

Thread Sealing Patch

The material is positioned in a 360deg band around the threaded portions of the fastener; when rotated against its mating thread, causes the capsules of adhesive to burst, releasing the material in and around the thread flanks, which then cures and forms a solid fill locking band. Note that a nylon patch that has been applied a full 360° around the thread will provide both a sealing and locking action. A sealing patch is typically used on pipe or hydraulic fittings to ensure that the threads provide a leak proof seal when assembled. Sealing patches are typically made using special or softer materials that create a liquid tight seal in the thread. Sealing patches are applied a full 360° around the threads. On pipe and hydraulic fittings, the first one to two threads are left free of the patch material and then the remaining threads are coated. For screw threads the sealing patch is typically applied to the first five to ten threads of the screw.

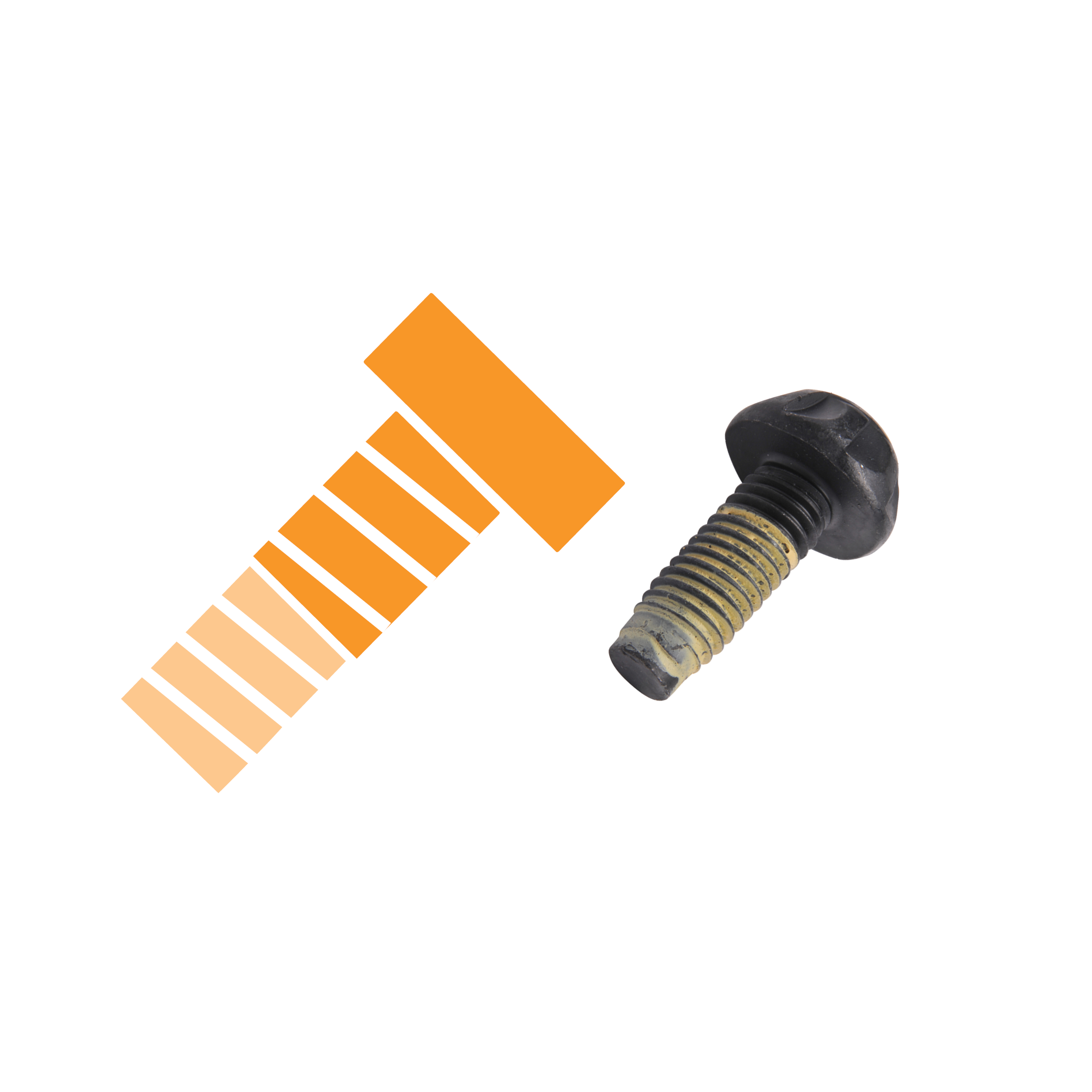

Thread Lubricants and Waxes

A range of processes developed to prevent fastener seizing, reduce installation torque, limit material adhesion, and more. Our masking and lubricating processes help customers decrease assembly and disassembly time which leads to an increase in productivity. Pre-Applied fasteners are ready for use right out of the box with no curing or drying required.

For more information on our patching capabilities or any of our other secondary processes, contact us at: +44 (0)1686 621 300or emailsales@hafrenfasteners.com.